What Are Cantilever Gate Rollers and How Do They Work?

A cantilever gate is a sliding gate that operates without ground tracks or wheels. Instead of rolling along a surface, it is supported by cantilever rollers mounted on a post, allowing the gate to slide smoothly while remaining elevated above the ground. This design makes it ideal for areas where ground conditions, such as dirt, snow, or gravel, could interfere with traditional sliding gate tracks. By eliminating ground contact and using cantilever rollers for support, these gates provide a long-lasting, low-maintenance, and efficient solution for secure access control.

How Cantilever Gates Differ from Traditional Sliding and Swinging Gates

No Ground Tracks Needed: Unlike traditional sliding gates, which rely on a track laid on the ground, cantilever gates are suspended using a roller system. This eliminates issues caused by debris or uneven surfaces.

Space Requirements: Swinging gates require a large clearance area to open, while cantilever gates move parallel to the fence line, making them more space-efficient.

Durability and Low Maintenance: Since cantilever rollers allow the gate to glide above the ground, there is less wear and tear compared to track-based sliding gates, which can accumulate dirt and debris over time.

Better for Heavy-Duty Use: Cantilever gates are commonly used in commercial and industrial settings because they can accommodate wider openings and heavier materials without the need for extensive ground preparation.

Common Applications of Cantilever Gates

Residential: Homeowners use cantilever gates for driveway entrances, offering a secure yet stylish solution without the hassle of ground tracks.

Commercial: Businesses prefer cantilever gates for parking lots, storage facilities, and restricted areas, where frequent access and security are priorities.

Industrial: Warehouses, factories, and high-security perimeters rely on cantilever gates due to their ability to support large, heavy-duty steel or aluminum frames while maintaining smooth operation.

How Does a Cantilever Gate Work?

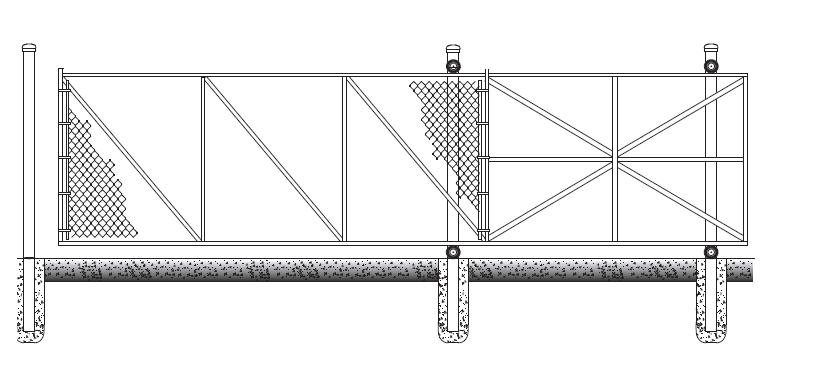

A cantilever gate operates using a suspended mechanism rather than relying on a track on the ground. Instead of rolling along a surface, the gate is supported by a series of cantilever rollers mounted on sturdy posts. These rollers allow the gate to slide open and close smoothly without direct contact with the ground, making it ideal for uneven, snowy, or debris-prone surfaces.

Understanding the Cantilever Mechanism

A cantilever gate operates using a counterbalance system, where a portion of the gate extends beyond the entryway to provide stability. This counterbalance section helps evenly distribute the gate's weight, ensuring smooth and reliable movement along the rollers without sagging or strain.

Key Components of the Cantilever Mechanism:

- Support Posts: These sturdy posts secure the roller brackets, providing essential structural support and ensuring the gate remains stable during operation.

- Gate Frame: The gate extends beyond the opening to create a balanced counterweight, preventing excessive strain on the rollers and allowing for smooth, controlled movement.

- Cantilever Rollers: Mounted on support posts, these rollers bear the weight of the gate, allowing it to slide effortlessly without touching the ground.

Because cantilever gates are elevated above the ground, they avoid the friction and obstructions that traditional sliding gates face. This makes them ideal for environments prone to snow, mud, gravel, or heavy traffic, where ground tracks would be difficult to maintain or keep clear.

Cantilever Gates: Nylon versus Steel Rollers

Cantilever rollers play a critical role in a cantilever gate's smooth and reliable operation. These rollers support the gate's weight and allow it to glide open and close without ground contact. Because cantilever gates do not rely on a track, the quality and type of rollers used significantly impact performance, longevity, and maintenance requirements.

Nylon Cantilever Rollers

Nylon rollers are popular for residential and light commercial applications due to their smooth operation and minimal maintenance requirements.

- Quieter Operation: Nylon rollers absorb vibrations and reduce noise, making them ideal for homes, gated communities, and noise-sensitive areas.

- Corrosion-Resistant: Unlike metal, nylon does not rust, making it an excellent option for coastal regions or humid environments.

- Smooth Motion: Nylon reduces friction, allowing for effortless gate movement with minimal resistance.

- Lower Load Capacity: While durable, nylon rollers are best suited for medium-weight gates and may not withstand the demands of heavy industrial gates over time.

Steel Cantilever Rollers

For commercial and industrial applications, steel rollers provide the strength and durability needed for heavier, high-traffic gates.

- Heavy-Duty Strength: Steel rollers can support significantly heavier gates, making them essential for warehouses, factories, and security perimeters.

- Greater Durability: Designed for frequent use, steel rollers handle high-impact and large-scale applications without wearing down quickly.

- Weather-Resistant (with Coating): Galvanized or stainless steel rollers resist corrosion, extending their lifespan in outdoor or extreme weather conditions.

- More Noise: Steel rollers tend to produce more sound during operation compared to nylon, which may be a consideration for noise-sensitive areas.

- Requires Lubrication: To maintain smooth operation and prevent rust, steel rollers need regular lubrication and maintenance.

How Many Cantilever Rollers Are Needed?

Gates Under 800 lbs & Up to 20 Feet Long

(Light to Medium-Weight Gates)

- Require four cantilever rollers, two mounted at the top and two at the bottom of the support post.

- This setup provides adequate support and balance while keeping friction and strain on the gate to a minimum.

- Ideal for residential driveways, light commercial applications, and small security gates.

Gates Between 800-1,500 lbs & 20-30 Feet Long

(Heavy-Duty Gates)

- Typically use six cantilever rollers, three at the top and three at the bottom.

- The additional rollers help distribute weight more evenly, reducing stress on each roller and preventing premature wear.

- Recommended for large commercial properties, gated communities, and industrial storage yards where moderate traffic is expected.

Gates Over 1,500 lbs & Over 30 Feet Long

(Industrial and High-Security Gates)

- Require eight or more rollers, typically four at the top and four at the bottom, but may vary based on the gate's weight and structural demands.

- This setup ensures maximum stability, preventing the gate from sagging or putting excessive stress on individual rollers.

- Best suited for airports, military bases, factories, and high-security perimeters where gates are heavy-duty and in constant use.

Nylon cantilever rollers are the best option for residential and light commercial applications where quiet, low-maintenance operation is preferred. However, steel rollers are the superior choice for large, heavy-duty gates requiring maximum strength and durability.

Regardless of the material chosen, using the correct number of rollers and ensuring proper installation and maintenance will significantly impact the gate's long-term performance and reliability.

Installation Guide: How to Build a Cantilever Gate

Installing a cantilever gate requires precise measurements, proper alignment, and secure mounting of the rollers and support posts. Below is a step-by-step guide to ensure a smooth installation.

Step 1: Preparing the Site and Measuring Correctly

- Measure the Gate Opening: Ensure that you account for the counterbalance section, which is typically half the length of the gate opening.

- Mark the Post Locations: Identify where the support posts will be placed, ensuring they are spaced correctly to support the cantilever rollers.

- Excavate and Set the Posts: Dig holes deep enough to support the weight of the gate (usually at least 36 inches deep, depending on soil conditions). Concrete is used to secure the posts and allow proper curing time.

Step 2: Mounting the Cantilever Rollers

- Install the Roller Brackets: Attach the top and bottom roller brackets to the support posts at the correct height.

- Mount the Cantilever Rollers: Secure the rollers to the brackets, ensuring they are level and aligned with the gate's path.

- Attach the Gate to the Rollers: Lift the gate and carefully position it onto the rollers. The bottom rollers should support the weight, while the top rollers guide movement.

- Install Any Additional Guide Brackets: Some heavy-duty gates may require extra support brackets for enhanced stability.

Step 3: Adjusting and Testing for Smooth Movement

- Check Gate Alignment: The gate should move freely and evenly along the rollers without dragging or misalignment.

- Test the Opening and Closing: Slide the gate multiple times to confirm smooth and stable movement.

- Make Necessary Adjustments: If the gate is too tight or loose, adjust the roller brackets and tension as needed.

- Secure All Fasteners: Ensure that all nuts, bolts, and brackets are tightened properly to prevent future shifting.

- Lubricate the Rollers (if using steel): Apply a suitable lubricant to reduce friction and prevent wear over time.

Cantilever Roller Covers

Cantilever safety covers are protective components for chain link fence gates, specifically cantilever sliding gates. These covers help prevent injuries by enclosing the exposed rollers and hardware, reducing the risk of accidental contact. Made from durable materials, they enhance the gate system's safety and longevity by shielding moving parts from debris and weather elements. Cantilever safety covers are commonly used in commercial and industrial settings to maintain a secure and efficient gate operation.

Installing cantilever safety covers is a straightforward process typically requiring basic tools. First, align the cover over the gate's roller mechanism, ensuring it properly encloses the moving parts. Then, use the provided mounting hardware to secure the cover to the gate framework, tightening any bolts or brackets as needed. Ensure the cover does not interfere with the gate's movement before finalizing the installation. Regular maintenance checks are recommended to keep the cover securely in place and functioning effectively.

Maintaining Your Cantilever Gate

Proper maintenance is essential to keeping a cantilever gate system operating smoothly for years. Regular upkeep extends the life of the gate and its components, prevents costly repairs, and ensures reliable security. The most critical part of maintenance involves taking care of the cantilever rollers, as they bear the weight of the gate and facilitate its movement.

Cleaning and Lubricating Rollers

Dirt, debris, and moisture can accumulate on the rollers, causing resistance and premature wear. Regularly clean the rollers with mild detergent and water, then wipe them dry to prevent rust and buildup. For steel rollers, apply a high-quality lubricant to keep them moving smoothly and reduce friction. Nylon rollers typically do not require lubrication but should still be cleaned to remove dust and debris.

Checking for Wear and Replacing Components as Needed

rollers, brackets, and fasteners may show signs of wear over time. Inspect the rollers for cracks, flattening, or rough movement and replace them if they no longer glide smoothly. Ensure that brackets and mounting plates remain tightly secured to the support posts, and check fasteners for rust or loosening. Replacing worn components promptly helps prevent further damage to the gate system.

Preventing Sagging and Ensuring Proper Alignment

A cantilever gate must remain properly balanced to function correctly. Periodically check the alignment by sliding the gate open and closed to see if it moves evenly without dragging. If the gate starts to sag, adjust the roller brackets or tensioning system to restore its position. Support posts should also be inspected for any movement or shifting, as unstable posts can lead to misalignment over time.

A cantilever gate system offers smooth, reliable operation without needing ground tracks, making it ideal for areas with uneven terrain, snow, or debris. Its trackless design reduces maintenance while providing enhanced durability and security for residential, commercial, and industrial applications. Key components include a sturdy gate frame, cantilever rollers (nylon or steel), support posts, roller brackets, and high-quality fasteners to ensure proper alignment and long-term functionality. ChainLinkFittings provides everything needed to build a complete cantilever gate system, offering premium-grade materials and hardware to ensure strength, reliability, and ease of installation.

If you have any questions, feel free to reach out; we're happy to help! You can also check out our Resources Hub for more information.

Contact Us Resources Hub