Cold-Rolling And Hot-Rolling Steel Pipe

Steel products vary in grade, shape, size, specification, and finish, many of which have unique properties. Steel pipe manufacturing has a significant impact on how it will be used across a wide range of industries. For prefabricated steel products, cold-rolled and hot-rolled determines the useability of steel pipe and make up the key differences between the two end products. Steel with differing grades or specifications can be manufactured through either hot-rolled or cold-rolled processes.

Hot-Rolled Steel Manufacturing Process

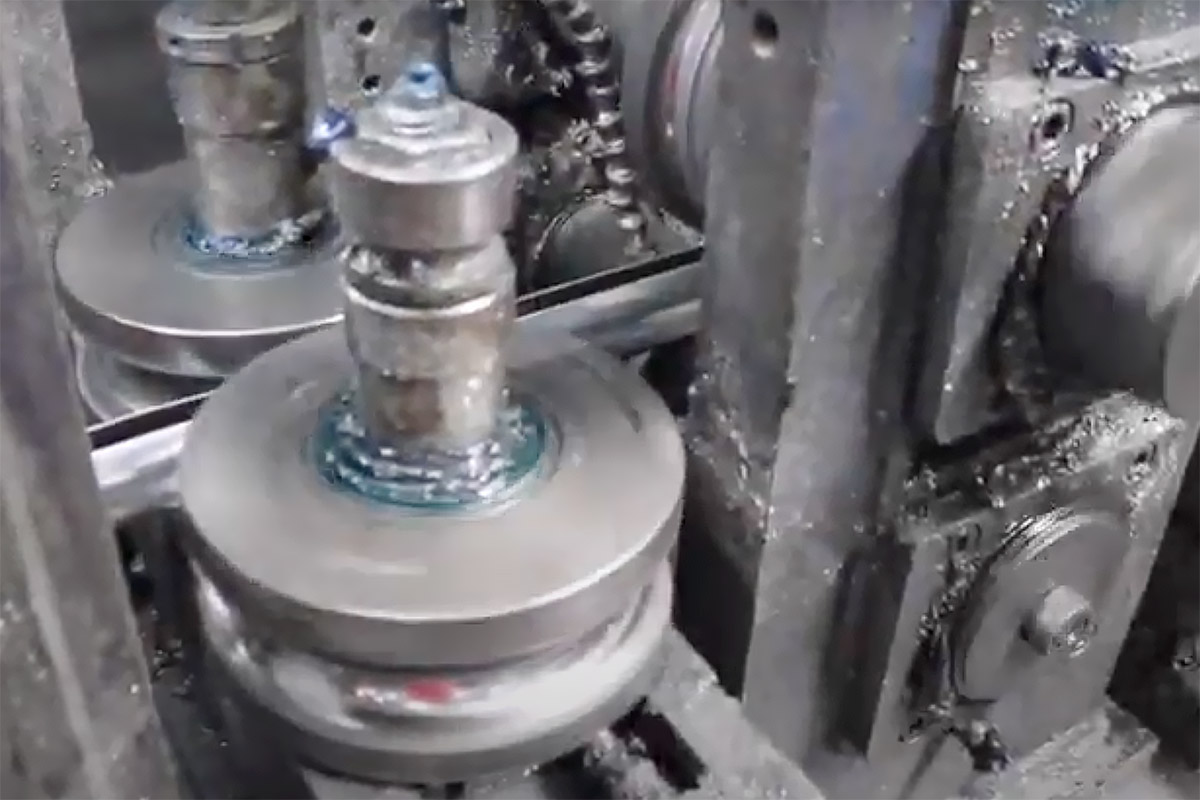

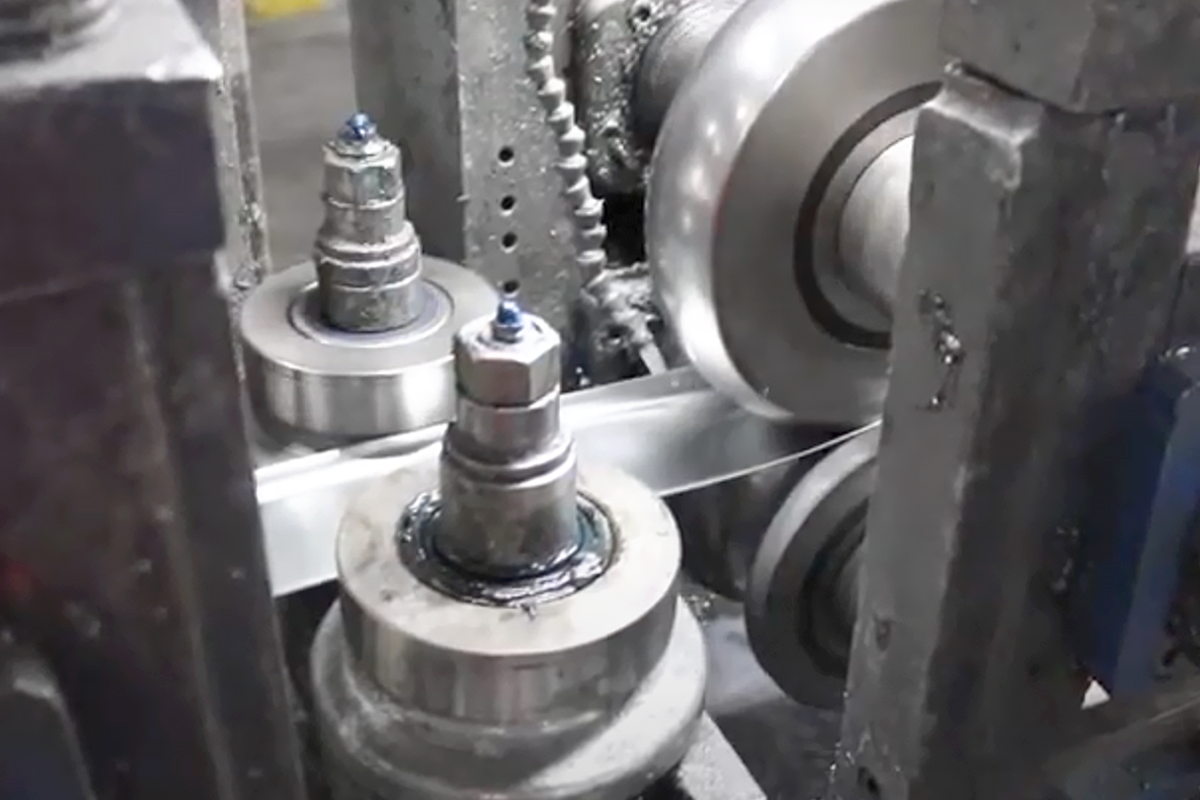

Hot-Rolling steel is the process of steel manufacturing through heat, generally separated into low, medium, and high-pressure boiler steel pipes. Hot-rolled steel has been roll-pressed at high temperatures of over 1,700 degrees which rises above re-crystallization threshold temperatures for most steel. Through this process, the steel is easier to form and work with. Manufacturing begins with a large, rectangular piece of metal called a billet. This billet is heated and sent over to be flattened into a roll. Keeping it at a high temperature, it is run (at high speeds) through a series of rollers until the desired dimensions are reached. Hot-rolled steel is cooled after it has been processed and will shrink slightly while it cools, meaning its final form is not as precise as cold-rolling is.

Ex. Hot-Rolling Seamless Steel Pipe Process

Round Billet → Heating → Perforation → Extrusion → Sizing → Hot Rolling → Cooling → Straightening → Hydrostatic Test → Signing → Storage

How To Identify Hot-Rolled Steel

- Scaled Surface - cooling from extreme temperatures

- Slightly Rounded Edges Or Corners - due to cooling process and shrinkage

- Distortions - due to cooling process and shrinkage

Cold-Rolled Steel Manufacturing Process

Cold-rolling steel is a process done near or at room temperature, but essentially is hot-rolled steel that has been taken further into processing. After the steel has been hot-rolled and cooled, it is re-rolled at room temperature for better specification of dimensions and higher quality surface qualities. Technically speaking, cold-rolled refers to sheets that undergo compression between rollers. However, cold-roll loosely describes a wide range of finishing processes in the steel industry, including turning, grinding, and polishing (furthering a hot-rolled item into a better and more refined end product).

Ex. Cold-Rolling Seamless Steel Pipe Process

Round Billet → Heating → Perforation → Annealing → Pickling → Anoint → Cold Rolling → Heating → Straightening → Hydrostatic Test → Signing → Storage

How To Identify Cold-Rolled Steel

- Finished Surface With Close Tolerances

- Oily Smooth Surface

- Uniformity And Straightness (Noticeable For Tubing)

- True Sizing, Defined Edges

Key Differences Between Cold-Rolled Pipe And Hot-Rolled Pipe

| Hot-Rolled | Cold-Rolled |

|---|---|

| low, medium, high-pressure boiler steel pipe, stainless steel pipe, oil cracking pipe, geological steel pipe, and other | low, medium pressure boiler tube, high-pressure boiler tube, alloy steel pipe, stainless steel pipe, and oil cracking tube, alloy thin wall steel tube, thin-walled stainless steel pipe, and special-shaped steel tube |

| Does Not Allow Local Buckling | Allows Local Buckling (Bending Bearing Capacity) |

| Distribution Of Residual Stress Is Film Type | Distribution Of Residual Stress Is Bending |

| Higher Free Torsional Rigidity (Better Torsion Resistance) | Lower Free Torsional Rigidity |

| Less Control Over End Result, Lower Dimensional Accuracy | High Dimensional Accuracy |

| Lower Quality Surface Characteristics | Smoother, Oily/Greasy Surface Characteristics, Sharp Edges |

| High Temperature Process, Then Cool Down (Less Control Over Shape) | Room Temperature Process Furthering Hot-Rolling (More Control Over Shape) |

| Highly Used In Agricultural Industry | Used For More Technically Precise Applications (Aesthetics) |

| Cheaper | More Expensive (Stronger Properties) |

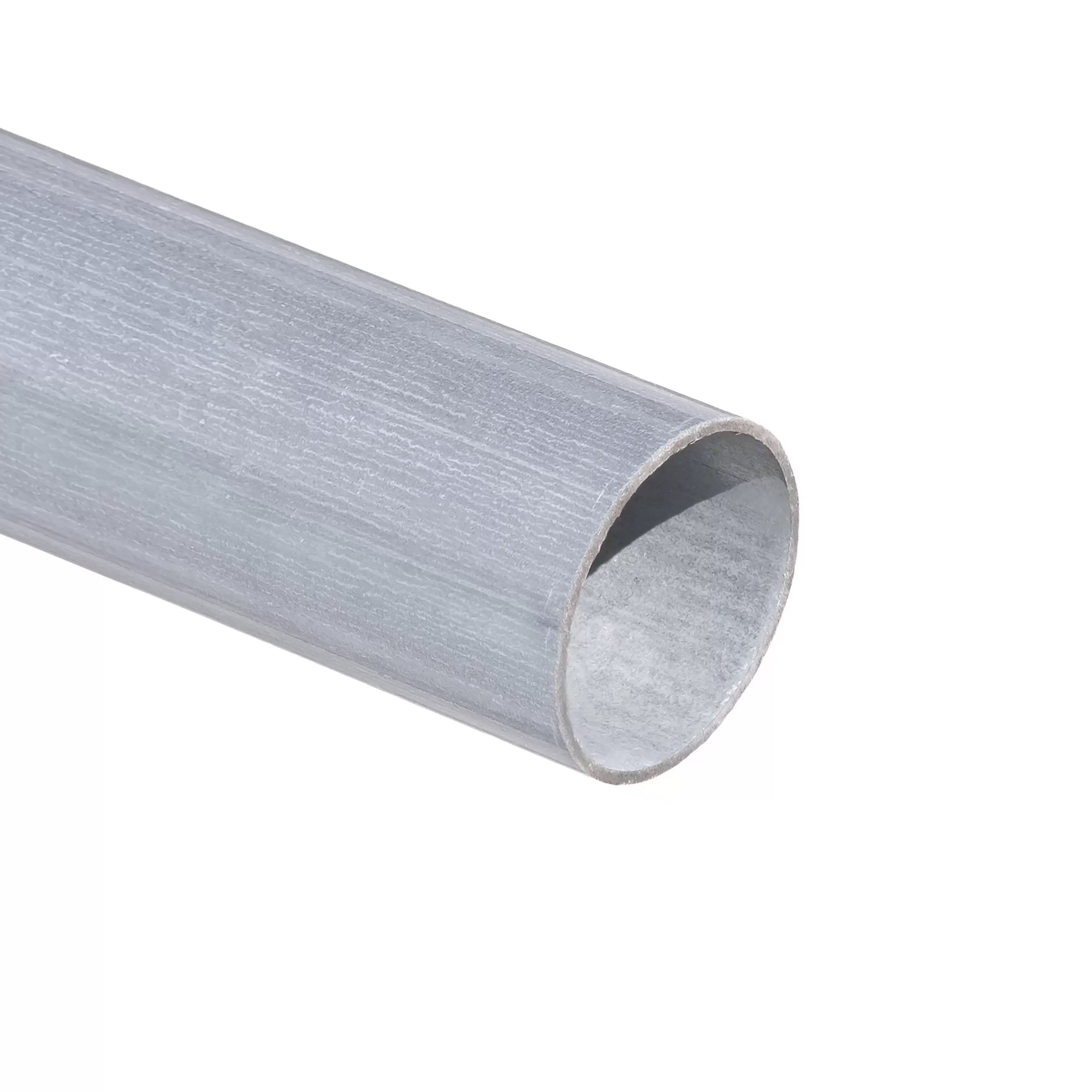

Where to Get Cold Rolled Steel

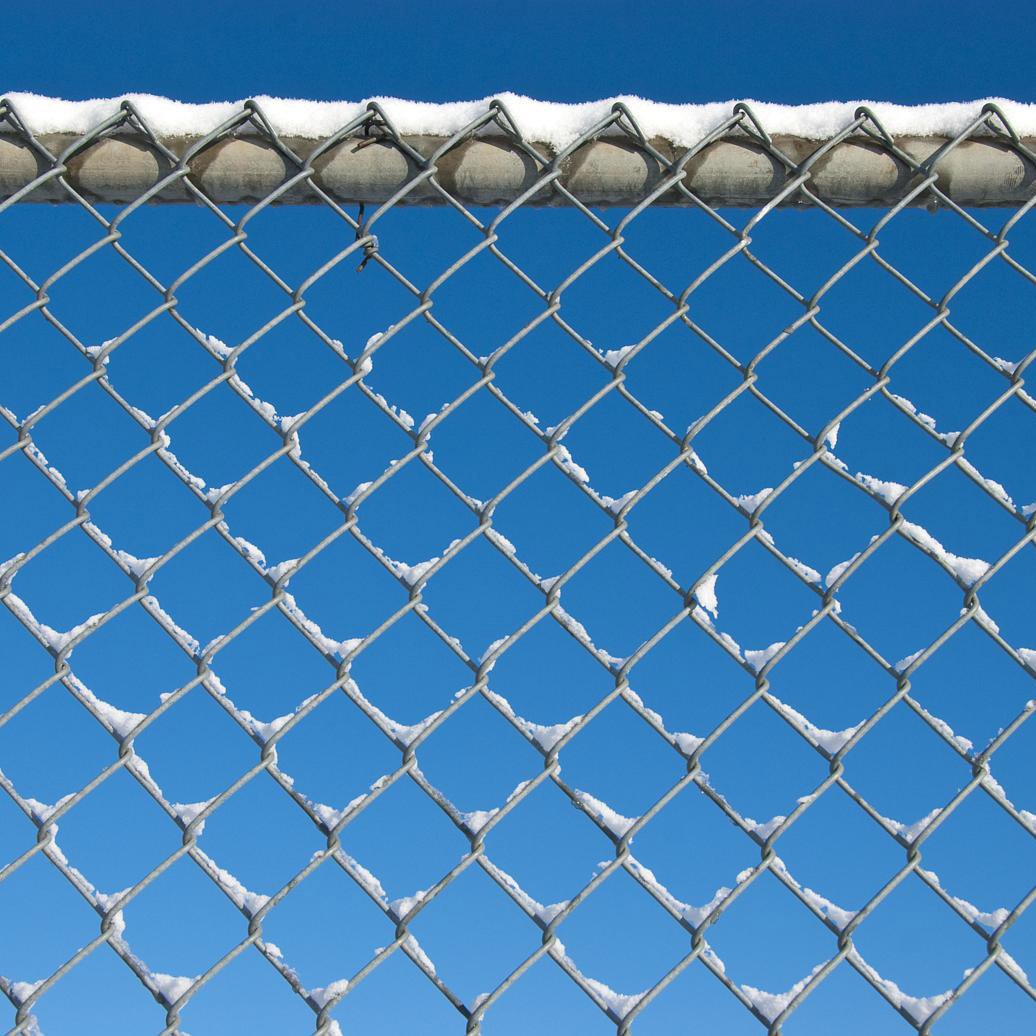

At Chain Link Fittings, ALL of our Piping & Tubing are made from the highest-quality Cold-Rolled Steel available today. Our cold-rolled steel tubing is manufactured with precision to guarantee uniformity in thickness, strength, and overall durability. Whether you need steel tubing for fencing, construction, or industrial applications, our selection is designed to meet rigorous standards while maintaining excellent performance over time. With superior structural integrity and corrosion resistance, our products offer long-lasting reliability in both indoor and outdoor environments.

We also offer a variety of sizes and specifications to match your project requirements, ensuring you get the perfect fit for your needs. Our galvanized coating enhances longevity by preventing moisture and environmental factors from compromising the steel’s surface. Browse our extensive catalog to find the ideal cold-rolled steel tubing for your specific use case, and feel free to reach out to our expert team for guidance on selecting the best option for your project.

Shop Cold-Rolled Tubing

Benefits Of Cold-Rolled Steel: Summary

Cold-Rolled Steel Strength

Significantly stronger than hot-rolled steel, cold-rolled steel is compressed by rollers at room temperature, which allows the steel to become stronger through strain hardening. Typically, cold-rolled steel is about 20% stronger than hot-rolled steel. This added strength makes it ideal for load-bearing structures, precision components, and high-stress environments. The controlled rolling process ensures consistent mechanical properties, reducing variations in tensile strength and overall performance. Additionally, this method enhances the steel's resistance to deformation, making it a preferred choice for industries that demand high-performance materials.

Tolerances Of Cold-Rolled Steel

The word "tolerance" in metalworking refers to the overall thickness of the metal material. Hot-rolled steel is typically thicker, while cold-rolled steel is thinner without compromising the strength. Because of this, cold-rolled steel has tighter tolerances that are unbeatable. These precise dimensions allow for better compatibility with machining processes, ensuring smoother fabrication and assembly. The improved dimensional accuracy also leads to reduced material waste, making it a more cost-efficient option for manufacturers. With minimal variations in thickness, cold-rolled steel is often chosen for projects that require exact measurements and consistent quality.

Does Cold-Rolled Steel Provide a Better Surface Finish

Cold-rolled steel has an improved, smooth surface compared to hot-rolled steel. Easy to differentiate from hot-rolled steel, cold-rolled steel has a smooth and often greasy or oily finish and fewer surface imperfections. More suitable for certain uses, cold-rolled steel is often selected because it is aesthetically nicer. The refined surface texture makes it easier to coat, paint, or plate, providing a clean and uniform base for finishing treatments. Its reduced oxidation and fewer scale deposits contribute to a higher-quality appearance and enhanced corrosion resistance. These characteristics make it particularly beneficial for applications where appearance and finish quality are essential.

Contact Us

When trying to build your fence, it's important to purchase the right parts for your needs, whether they are Hot-Rolled or Cold-Rolled! Whether it's a simple job like tightening your bolts or something as complex as replacing a fence post, Chain Link Fittings are here to help with all your durable fencing fitting needs. From Bolts and Bands to Paint and Primers, we have all of the tools to get your fence up quickly and securely!

If you have any further questions, please reach out to our sales representatives. They are happy to help in any way they can!

Contact Us Shop Cold-Rolled Tubing