How is Black Chain Link Mesh Made?

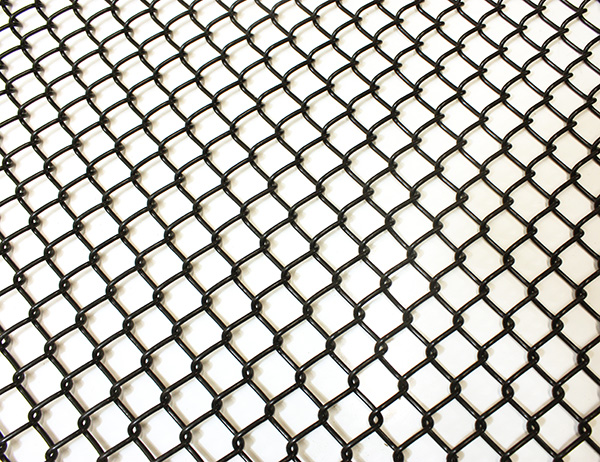

Chain link mesh, also known as chain link fabric, is a durable and flexible fencing material made from interwoven metal wires arranged in a diamond pattern. Typically constructed from galvanized steel or aluminum, it is widely used for security, containment, and boundary applications. Its strength, affordability, and ease of installation make it a popular choice for residential, commercial, and industrial fencing.

Black chain link fencing has become increasingly popular due to its modern, sleek appearance and added durability. Homeowners appreciate its ability to blend with landscaping while providing security, while businesses and industrial sites favor it for its low maintenance and weather-resistant properties. The manufacturing process involves weaving metal wires into a mesh using specialized machinery, cutting it to size, and either leaving it galvanized or applying a protective coating. Coatings such as vinyl or powder help enhance durability, prevent rust, and provide a smooth, attractive finish.

What Makes Chain Link Fencing Black?

Black chain link fencing is available in two primary coating methods: vinyl coating and fused and bonded (powder) coating. Each method provides protection against rust and corrosion while offering a sleek black finish, but they differ in durability and application.

Method 1: Vinyl-Coated Chain Link Mesh:

This process involves applying a layer of polyvinyl chloride (PVC) over galvanized steel wire to enhance durability and resistance to corrosion. First, the steel is thoroughly cleaned and galvanized to protect it from rust. Then, a layer of vinyl is either extruded or bonded onto the wire, forming a smooth and protective outer coating. This method not only improves the fence's weather resistance but also provides an affordable and visually appealing solution. However, over time, vinyl coatings may wear down or split, particularly in harsh weather conditions. Powder-coated is a better and more commonly used method, offering superior durability, resistance to chipping or peeling, and a longer-lasting finish.

Method 2: Fused and Bonded (Powder-Coated) Chain Link Mesh:

Powder coating is a durable and advanced method used to coat chain link mesh. The process begins with cleaning and preparing the steel, followed by electrostatically applying a dry powder coating. The coated metal is then heated, allowing the powder to bond and create a smooth, protective finish. This method ensures superior durability, resistance to chipping or peeling, and long-lasting protection against weather and corrosion.

- Cleaning & Preparation: The steel is thoroughly cleaned to remove dirt, oil, and contaminants.

- Powder Application: A dry powder coating is electrostatically applied to the metal surface.

- Heating & Bonding: The coated metal is placed in an oven, where heat fuses the powder to the surface.

- Cooling & Final Finish: The metal is cooled, creating a smooth, durable, and weather-resistant coating.

Learn more about the chain link mesh and fittings powder-coating process here: Why Choose Powder-Coated Chain Link Fencing? The Process and Benefits.

Comparative Analysis: Vinyl Coated vs. Powder-Coated Chain Link Fencing

Both vinyl coating and fused and bonded (powder) coating are used to enhance the durability and appearance of chain link fencing. However, they differ in terms of longevity, weather resistance, and cost-effectiveness. While vinyl-coated chain link mesh is a cost-effective and visually appealing option, fused and bonded (powder) coating is the better choice for durability and weather resistance, making it the preferred method for long-term fencing solutions.

Vinyl-Coated Chain Link Mesh

- Durability: Prone to splitting or peeling over time, especially in extreme temperatures or high-impact areas.

- Weather Resistance: Provides moderate protection but may degrade faster in harsh conditions such as prolonged sun exposure or heavy moisture.

- Cost: More affordable due to its simpler application process, making it a budget-friendly option for residential and light commercial use.

Fused and Bonded (Powder-Coated) Chain Link Mesh

- Durability: More resilient, as the powder coating forms a bonded layer that resists chipping, cracking, and peeling.

- Weather Resistance: Superior performance in extreme weather conditions, including UV exposure, heavy rain, and fluctuating temperatures.

- Cost: Higher upfront cost due to the advanced application process, but offers long-term savings with reduced maintenance and longer lifespan.

Both vinyl and powder-coated chain link fencing offer a more refined and durable alternative to non-coated steel. While vinyl coating provides an affordable and visually appealing option for residential and low-impact areas, powder coating offers superior durability, weather resistance, and longevity, making it ideal for high-traffic or extreme environments. For long-term performance, powder-coated fencing remains the preferred choice.

When selecting chain link fencing, it's important to consider factors such as coating type, durability, and maintenance needs. If you have any questions about chain link fabric, fittings, or the powder-coating process, our expert Sales Representatives are here to help. Whether you're choosing the right coating, exploring customization options, or need assistance with installation, we're committed to providing expert guidance. Contact us today for personalized support in selecting the best fencing solution for your project!

Where to Order Chain Link Fence Mesh

For high-quality chain link fence mesh, AluminumChainLink and DomesticFenceFittings, are part of the DF Supply Inc. Family, offers a variety of fencing materials, including aluminum chain link fabric for corrosion resistance and galvanized chain link mesh for durability. To ensure you receive the right size, finish, and specifications for your project, contact us directly to place your order. Our team is ready to assist you.

How to Order Chain Link Fence Mesh

Customizing chain link fence mesh to your needs requires careful selection of key specifications. Before placing your order, consider the following:

- Height & Length: Specify the required fence height and total length.

- Mesh Size: Choose from standard or custom diamond mesh sizes.

- Coating Type: Select galvanized, vinyl-coated, or powder-coated finishes for added durability.

- Wire Gauge: Determine the appropriate wire thickness based on security needs.

- Selvage Type: Opt for knuckled selvage for safety or barbed selvage for enhanced security.

If you need assistance selecting the best option for your project, our team is here to help. Contact us today to get expert guidance and ensure you receive the perfect chain link fencing solution.

Contact Us